Measurement of the color temperature of light.

Illumination is measured with a light meter, while using a color temperature meter we can determine its color. Before we explain how this instrument works with reversible materials, we must first expand and clarify the meaning of the term "color temperature of light". As everyone knows, an incandescent lamp gives a more yellow light than sunlight, the latter being different in heavy cloud cover and fine weather. The term "more or less yellow" is naturally very imprecise, and we should adopt some fixed scale of comparison, to make such markings. Such a comparative scale is the scale of an incandescent black body. If we put iron in a blacksmith or blast furnace and heat it, it will first take on the color of cherry embers, then red heat, then yellow glow, until it turns white in color. Each temperature of the iron corresponds to a specific glow color associated with it, specific light radiation of a heated body. Heated bodies of the same color show the same glow color at higher temperatures, as long as they naturally tolerate higher temperatures. Black bodies, however, radiate more blue rays at the same temperature than gray or white bodies. They emit light, which in the case of iron can only be achieved at high temperatures. A perfect black body was used as a comparison body.

You should still pay attention to this, that we can measure temperature not only in degrees Celsius or Fahrenheit, but also in degrees Kelvin. The conversion is very simple, because degrees Kelvin can be expressed as degrees Celsius + 273°, i.e. that they give the temperature in units of Celsius above absolute zero.

On this scale we can measure the color of light of all bodies that radiate light. Gas discharges cannot be classified as such, because sent by, no light is not caused by heating. We are then talking about the so-called cold light, because its spectral composition does not correspond to the spectrum of radiation emitted by heated bodies. This is also the case with xenon lamps as well as xenon-containing electron flash lamps. Fluorescent lamps emit green light caused by discharges in mercury vapor, however it appears to the eye, that they emit light similar to an incandescent lamp or, depending on the type, similar to daylight. This is due to the change in energy on the phosphor inside the lamp.

Reporting the color of the light source in degrees Kelvin, however, was not satisfactory, and therefore a step forward was made, so that you can easily evaluate properties and perform calculations when selecting filters. A second definition of color temperature has been introduced, namely "mired". This word is of American origin and was created from the abbreviation "micro reciprocal degree". The word "mired" already includes the word degree (degree), so that one should not say "degrees mired". Mired is the reciprocal of millionths of a value expressed in degrees Kelvin or, how else can we define it, mired (M) is equal 1 000 000 — 106 divided by degrees Kelvin:

M=106/K

Decamired is equal 10 M.

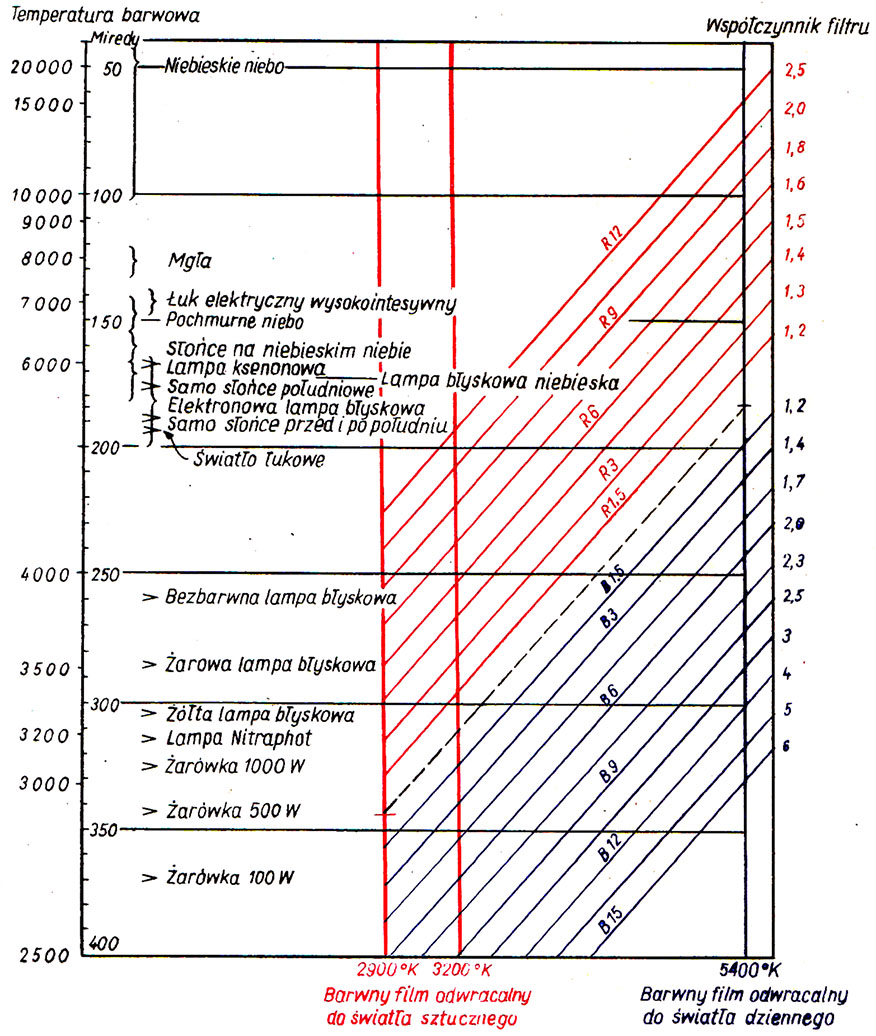

In the figure on the left, the Kelvin and Mired values correspond naturally to the above formula, i.e. higher temperatures correspond to higher degrees of Kelvin, but lower values in mireds.

The great advantage of mireds is this, that in decamireds we can specify the colors of filters used to equalize the color temperature of light used especially for reversible materials. The markings have been chosen in this way, that they can be easily adapted to the color temperature conditions of the operating light. The difference between the measured value and the recommended value for a given type of color film is calculated in mireds and the lens is covered with filters of the corresponding number. The numbers determining the color of light in mireds are very simple; depending on the filter values, they increase (pink filters) or lower (blue filters). More serious manufacturers have introduced sets of photo filters consisting of two series of pink and blue colors., each having filters of 1.5-3-6-12 mired. Threaded or cap handles are constructed this way, that filters can be stacked on top of each other to obtain intermediate values. When used correctly, any color distortion on reversible films can be prevented, and it only applies to them, because negative films can be corrected during the copying process. It is also possible to match the properties of different products or to adjust the properties of emulsions of the same type that differ in color from each other, not to deal with a lot, but with only one emulsion number. However, these activities should be performed by a professional. Based on the test images, we can assess the desirability of using a weak filter or calculate it on the basis of the first film, if the color temperature meter or graph shown in Fig. 1 they will keep us informed, that the light illuminating the object has deviations from the recommended Kelvin values. A completely bright yellow filter can also be useful for this purpose, with an optical density corresponding to the Agfa or ORWO filter no 32, giving good results in combating blue and purple smoke.